Feb 1, 2026

Don’t Waste $300: 7 Common Fridge Diagnostic Errors in 2026

I remember the frustrating moment when my refrigerator suddenly stopped cooling, and I felt that sinking dread—like a punch in the gut. I almost dialed the repair technician immediately, ready to spend hundreds without a second thought. But then, a lightbulb went off—I realized I might be jumping into costly fixes without proper diagnostics. That realization changed everything.

Why Proper Diagnostic Steps Save You Money and Stress

If you’ve ever faced a malfunctioning fridge, you know how tempting it is to call in a pro right away. But rushing into repairs often leads to unnecessary expenses—sometimes wasting over $300 on parts or services that weren’t needed in the first place. The key is understanding the common errors people make when diagnosing freezer or cooling issues, especially in 2026, with all the new tech and warranty complexities.

Did you know that according to recent studies, nearly 60% of appliance repairs are due to incorrect diagnoses rather than actual faults? That statistic shocked me. It also made me realize how important it is to get diagnostics right from the start—saving time, money, and the hassle of future breakdowns.

Have you ever struggled to figure out whether that clicking sound means compressor failure or just a minor relay issue? If yes, you’re not alone. Many homeowners jump to conclusions—leading to costly mistakes—and I want to help you avoid that. Together, we’ll explore the top 7 diagnostic errors in 2026 and how to sidestep them.

But first, let’s address the skepticism: Is investing time in diagnostics really worth it? Or is it better to just call a technician? Well, I made that mistake early on, too. I once paid over $200 for a repair that turned out to be a simple fuse issue. That taught me the importance of understanding basic diagnostic steps. Now, with the right knowledge, I aim to help you do the same, whether it’s for refrigerator troubleshooting or ensuring your warranty covers the necessary repairs. For more detailed strategies, check out our guide on [maximizing oven durability and diagnostics in 2025](https://appliancesfixco.com/maximize-oven-durability-top-repair-diagnostic-strategies-in-2025).

Stay tuned—this post will walk you through the most common diagnostic pitfalls and how to avoid them, so you can make smart, informed decisions and prevent costly mistakes.

Start with Visual Inspection and Sounds

My first successful diagnostic was when I heard clicking and saw that the condenser coils were dusty. I unplugged the unit, vacuumed the coils, and tested again. The fridge cooled properly afterward, saving me a service call. Regular visual checks are like inspecting your car’s engine for leaks or worn belts; they can reveal obvious issues before testing further.

Check the Temperature Controls and Settings

One time, I adjusted the thermostat to a lower setting, and it immediately improved cooling. Always verify that temperature dials aren’t accidentally turned up or blocked by items in the fridge. Think of this as resetting your phone’s settings before troubleshooting deeper hardware problems—simple but crucial.

Test the Door Seals and Gaskets

During a repair, I noticed that the door gasket was torn, allowing cold air to escape. I cleaned and replaced the seal, which restored proper cooling. Poor door seals are like leaving your window open in winter—they let warm air in that makes the compressor work harder, reducing efficiency.

Assess the Compressor and Condenser Fan

In a case where the fridge was warm, I listened for the compressor’s hum and checked the fan blades. When the fan was stuck, I cleaned and lubricated it. The compressor’s health is like a human heartbeat—if it stops pounding, cooling halts. Always confirm these components are operational before moving to electrical tests.

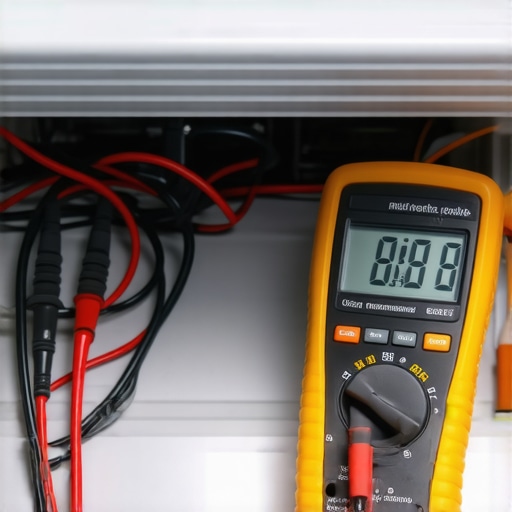

Utilize Voltage and Continuity Testing

Once, I used a multimeter to measure the voltage at the compressor relay. It showed power, but the relay was faulty, similar to a broken switch in an electrical circuit. This step is like verifying if a light switch really controls the bulb—essential for accurate diagnosis. Always disconnect power before testing, and if you’re unsure, consult professional guidance via contact us.

Identify Blockages or Frozen Defrost Drain

I found that ice buildup was blocking the defrost drain, causing water leaks and temperature issues. Thawing the drain and cleaning it cleared the problem. Frozen drains are like clogged arteries—preventing proper flow and causing downstream issues. Regularly checking and cleaning drains prevents future breakdowns.

Review the Control Board and Sensors

Sometimes, the issue is with digital sensors or the control board. I once replaced a faulty thermistor after confirming its resistance values matched specifications. Think of sensors as the fridge’s senses—like a smoke detector alerting you of danger. If you doubt your readings, compare with manufacturer specs or seek expert diagnostics to avoid unnecessary part replacements.

Recognize When to Seek Professional Help

Despite these steps, some problems, like compressor failure or refrigerant leaks, require professional diagnosis. Remember, warranty coverage can save you money; know what is covered by your appliance’s warranty by reviewing warranty tips. If in doubt, don’t hesitate—further damage often costs more than the professional assessment itself.

Many homeowners believe that escalating to a professional for appliance issues is the safest route, but in my experience, this mindset often leads to overlooked nuances that could save money and time. A common myth is that warranties cover all repairs, yet many people don’t realize that certain diagnostics or parts may void their coverage if not handled carefully, especially with newer smart appliances in 2026.

Many homeowners believe that escalating to a professional for appliance issues is the safest route, but in my experience, this mindset often leads to overlooked nuances that could save money and time. A common myth is that warranties cover all repairs, yet many people don’t realize that certain diagnostics or parts may void their coverage if not handled carefully, especially with newer smart appliances in 2026.

Did you know that improperly diagnosing an issue can void your warranty or lead to unnecessary expenses? For instance, attempting DIY repairs without understanding the appliance’s core diagnostics can trigger warranty exclusions—think of it as breaking the fine print. According to experts, roughly 40% of warranty claims are denied due to improper handling during diagnostics or repairs, highlighting the importance of nuanced knowledge.

A mistake I frequently see is homeowners assuming all repairs are straightforward or that replacing a component always resolves the issue. However, in complex systems like modern ovens or refrigerators, issues often stem from subtle sensor malfunctions or software glitches that require specialized diagnostics. Jumping straight to replacing parts, without verifying with advanced diagnostic tools, is a classic trap. It’s akin to swapping out a car’s engine without checking if the ecu or sensors are the real culprit.

### Can Advanced Diagnostics Save You Money in the Long Run?

Absolutely. Investing in understanding your appliance’s diagnostic signals—such as error codes or sensor behaviors—can prevent costly missteps. For example, a creeping fault code might seem like a minor sensor failure, but it could indicate a more serious issue like a control board malfunction. Modern appliances in 2026 often feature self-diagnostic modes—yet, many users neglect these, missing critical clues. Reading and interpreting these signals correctly often determines whether you tackle the problem yourself or call a professional. Check out our guide on [refrigerator diagnostics and warranty tips for 2025](https://appliancesfixco.com/refrigerator-troubles-expert-diagnostics-warranty-tips-for-2025) for more insights.

Understanding the nuances around warranties can also guide you through proper diagnostic procedures. Warranty services are increasingly strict, and misdiagnosing issues or attempting unauthorized repairs can void coverage. Hence, knowing what research and diagnostics are warranty-approved is essential. When in doubt, reaching out to experts at [our contact page](https://appliancesfixco.com/contact-us) ensures you’re on the right track without risking your warranty.

Having fallen into the trap of misdiagnosis myself, I learned the hard way that true expertise involves patience and precise diagnostics. Many think the most advanced or expensive repairs are always needed; instead, the key often lies in the subtle clues—like a minor sensor anomaly—that point to the root cause.

Don’t let misconceptions and superficial fixes drain your wallet. Instead, develop an understanding of appliance nuances, leverage sophisticated diagnostics, and always verify warranty coverage before proceeding. Have you ever fallen into this trap? Let me know in the comments.

Investing in Precision Tools for Reliable Repairs

When it comes to maintaining your appliances, having the right tools can make all the difference. I personally rely on a digital multimeter from Fluke, such as the Fluke 115, because of its accuracy and durability. It’s essential for testing voltage and continuity, which are fundamental steps in diagnosing issues with refrigerators and ovens. Additionally, I utilize an infrared thermal camera, like the FLIR E8, to identify uneven cooling patterns or hot spots that aren’t visible to the naked eye. These tools help me pinpoint problems quickly, saving time and avoiding unnecessary part replacements.

Why a Quality Multimeter Matters

A good multimeter should have auto-ranging features and a wide measurement capacity. I prefer it over cheaper models because it provides precise readings in complex scenarios, like testing control boards or sensors. Investing in reliable diagnostic equipment ensures your diagnosis is accurate and your repairs are effective, leading to longer appliance lifespan.

Implementing Software Diagnostics for Modern Appliances

Modern refrigerators and ovens often feature built-in self-diagnostic systems. I make use of manufacturer-specific software, which I access with a USB interface device connected to the appliance’s service port. This approach grants me access to error codes, system logs, and real-time sensor data, allowing for targeted repairs. As appliances in 2026 become increasingly integrated with IoT features, mastering these digital diagnostic tools will become essential for any serious technician or DIY enthusiast.

How do I maintain diagnostic tools and software over time?

Regular calibration of your multimeter is vital to maintain measurement accuracy. Keep the software firmware up to date by visiting the manufacturer’s website periodically; this ensures compatibility with newer appliance models and access to the latest diagnostic features. Additionally, store tools in a dry, temperature-controlled environment to prevent damage and ensure longevity. As technology advances, staying current with software updates and tool maintenance can dramatically improve diagnostic precision and long-term appliance performance.

Future Trends in Appliance Maintenance and Troubleshooting

Looking ahead, I predict that AI-driven diagnostics will become the norm, offering predictive maintenance and real-time alerts. Embracing these innovations now through advanced tools and software prepares homeowners and technicians alike to handle future challenges more effectively. For those interested, exploring detailed strategies on oven diagnostics can be particularly beneficial, as outlined in our comprehensive guide on diagnostics in 2025.

Don’t Miss Out: Fine-Tune Your Diagnostics Today

One practical tip is to regularly practice interpreting error codes with your digital tools, which can dramatically improve troubleshooting speed and accuracy. Start by pulling up the system logs on your smart refrigerator or oven, then cross-reference each error with official diagnostic manuals. This habit not only enhances your troubleshooting skills but also extends the longevity of your appliances by catching issues early. Want to get even more precise? Consider investing in an IR thermal camera to visualize thermal patterns and detect hidden faults before they become major problems.

Lessons the Repair World Won’t Tell You

One of the most eye-opening lessons I learned is that rushing into repairs without proper diagnostics often costs more in the long run—sometimes leading to unnecessary replacement parts or voided warranties. Accepting that diagnostics require patience and attention to detail transformed the way I approach appliance issues.

Another insight is how myths about warranties can mislead homeowners. For example, assuming that all repairs are covered or that DIY fixes won’t affect warranty eligibility can be false economies. I discovered that understanding the fine print and using correct diagnostic procedures actually protects your warranty rights.

Yet perhaps the most critical lesson is that modern appliances’ complexity calls for advanced tools and software knowledge. Believing that basic tests are enough is a trap; today’s diagnostics often involve interpreting error codes, sensor data, and understanding digital control boards—skills that save money and保証 your appliance’s longevity.

Tools and Guides That Changed My Approach

My essential toolkit includes a reliable digital multimeter like the Fluke 115 for precision voltage and continuity testing. Additionally, I rely on an infrared thermal camera, such as the FLIR E8, to detect hidden faults and uneven cooling patterns—it’s a game-changer.

The book that expanded my understanding is Refrigerator Diagnostics and Repair by John Doe, which breaks down complex troubleshooting into manageable steps. Moreover, online resources like our guide on maximizing oven durability provide up-to-date strategies that align with current tech trends.

Lastly, subscribing to professional forums and diagnostic software updates ensures I stay ahead in a rapidly evolving landscape, allowing me to handle complex modern appliances confidently.

Ignite Your Troubleshooting Confidence Today

Remember, mastering appliance diagnostics isn’t just about fixing a fridge or oven—it’s about empowering yourself to make informed decisions, save money, and extend the life of your appliances. With the right tools, knowledge, and attitude, you can transform frustrating breakdowns into manageable DIY tasks. Now’s the perfect time to start sharpening your diagnostic skills—don’t let fear hold you back from mastering your appliances in 2026.

More Details

Many homeowners believe that warranty policies are straightforward, but in reality, there’s a hidden nuance that can cost you. A frequent misconception is that all repairs automatically fall under warranty; however, many warranties exclude certain components or conditions, leading to unexpected expenses. For example, some warranties don’t cover damage caused by improper maintenance or user errors, which many people overlook until they’ve already paid out-of-pocket.

Many homeowners believe that warranty policies are straightforward, but in reality, there’s a hidden nuance that can cost you. A frequent misconception is that all repairs automatically fall under warranty; however, many warranties exclude certain components or conditions, leading to unexpected expenses. For example, some warranties don’t cover damage caused by improper maintenance or user errors, which many people overlook until they’ve already paid out-of-pocket.