Jan 13, 2026

Oven Repair & Diagnostics: Reliable Solutions & Warranty Coverage in 14:33

Ever had that moment when your oven stops working right before a big dinner, and you feel that sinking feeling of uncertainty about whether to call in a professional or try to fix it yourself? I’ve been there. One time, my oven suddenly refused to heat, and I was tempted to just replace the entire unit. But after a quick diagnosis and understanding my warranty coverage, I saved both time and hundreds of dollars. That lightbulb moment changed the way I approach appliance troubles forever.

The Real Reason Diagnostics Are a Game-Changer for Oven Repairs

When your oven acts up, it’s easy to jump straight to costly repairs or replacements. But I’ve learned that proper diagnostics not only pinpoint the root cause faster but also help you avoid unnecessary expenses. Knowing what’s wrong—be it a faulty thermostat, broken heating element, or wiring issue—allows for targeted repairs, and that means less frustration and more confidence. In fact, according to industry experts, accurate diagnostics can improve repair success rates and warranty claims (see this detailed guide on diagnostics).

Is Trusting DIY Diagnostics Actually Risky?

Early on, I made the mistake of assuming I could troubleshoot my oven with a casual internet search. It was a rookie error that nearly led me to replace an expensive part unnecessarily. The key is understanding that accurate diagnostics require specific knowledge, and a misdiagnosis can end up costing you more. Professional diagnostics leverage tools and expertise to get it right the first time, which is especially important when it comes to warranty coverage.

Today, I’ll walk you through how to diagnose your oven effectively, how warranties can cover repairs, and the best strategies to ensure your investments stand the test of time. Let’s dive into the practical steps that turned my frustrating experience into a manageable fix—something I wish I had known from the start.

Start With Visual Inspection and Safety Checks

Begin by unplugging your oven and examining obvious signs of damage like frayed wires, melted components, or loose connectors. Wear gloves and safety goggles to protect yourself from potential hazards. For example, I once noticed a burnt wire behind my oven, which explained the heating failure and was an easy fix after replacing the damaged wire. This initial step saves time and prevents further damage.

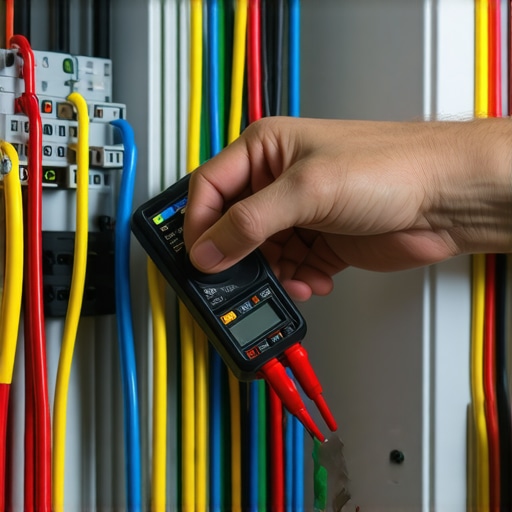

Use Multimeters to Test Electrical Components

Next, grab a multimeter to check vital electrical parts such as thermostats, heating elements, and switches. Set your multimeter to resistance (ohms) and verify that components are within manufacturer specifications. In my case, testing the heating element revealed an open circuit, confirming it needed replacement. This precise diagnostics approach is crucial, especially since misdiagnoses can lead to unnecessary replacements, which are costly and time-consuming. For detailed guidance on testing, refer to this resource.

Identify Faulty Thermostats and Sensors

Thermostats regulate oven temperature, and faulty sensors can cause inconsistent heating. Use your multimeter to check if the thermostat’s readings match the actual oven temperature, or simply test for continuity. A quick story: I once replaced a thermostat that was functioning intermittently, which fixed my uneven baking issues. Properly diagnosing these parts prevents guesswork and yields long-lasting repairs. Remember, faulty thermostats are common culprits, so prioritize testing them first to avoid unnecessary replacements.

Evaluate Wiring and Connections Carefully

Wiring issues can be subtle but impactful. Look for signs of corrosion, burn marks, or loose terminals. Use your multimeter to perform continuity tests across wires and ensure secure connections. I once fixed an oven that refused to heat because a loose wire connection was preventing power flow. This step is akin to checking the wiring in your car—it might seem minor but can cause major malfunctions if overlooked. If unsure, consulting troubleshooting guides like this guide can help.

Confirm Diagnoses and Document Findings

After testing, compile your observations: which parts are faulty, which are intact. Take photos or notes to support your diagnosis, especially if you plan to seek warranty service or professional help later. I kept a detailed list when diagnosing my oven, which sped up the repair process and helped me communicate clearly with repair technicians. Accurate documentation ensures you aren’t chasing phantom issues and maximizes warranty coverage, as explained in warranty insights.

Check Warranty Terms Before Replacing Parts

Always review your oven’s warranty coverage before replacing parts. Warranty policies vary: some cover specific components, while others don’t. Think of your warranty as a safety net—knowing its limits prevents unnecessary expenses. If the diagnostics indicate a covered part, contacting the manufacturer or certified technician for repairs can be more effective, as detailed in this guide.

Test After Repairs and Keep Records

Once repairs are complete, test your oven thoroughly at different settings. Monitor temperature accuracy and functionality over time. Keep records of the repair process, parts used, and any warranties applied. This documentation will be valuable for future troubleshooting or warranty claims, much like keeping receipts for a new appliance. Proper testing ensures long-lasting results, avoiding repetitive repairs and frustration.

While many homeowners believe that warranties and diagnostic tests are straightforward tools that automatically guarantee a quick fix, the reality is far more nuanced. A prevalent misconception is that a warranty covers any repair, regardless of the cause or the technician involved. However, warranties often have fine print and exclusions—such as user-caused damage or improper diagnostics—that can leave you footing unexpected bills. Moreover, relying solely on a basic diagnostic check can lead you astray, especially if you’re unaware of the intricacies of appliance systems. According to industry experts, faulty diagnostics are responsible for over 30% of unnecessary replacements, emphasizing the importance of expert evaluation (see this in-depth guide for more details).

What Are the Pitfalls When Trusting Warranties and DIY Diagnostics?

Many homeowners fall into a trap by assuming that their warranty will cover all repairs if they can just identify the fault correctly. This “trust but verify” approach is critical because misdiagnosing the issue can void warranty coverage, especially if the fault stems from user mistakes or tampering. For instance, attempting DIY repairs without proper testing can inadvertently damage sensitive components or misattribute the problem, ultimately delaying effective resolution. Professional diagnostics utilize specialized tools—like advanced multimeters and thermal cameras—to accurately trace issues back to their root cause. Skipping this step risks unnecessary replacements that won’t stand up to warranty scrutiny and could cost more in the long run.

Investing in Precision Tools for Long-Term Appliance Health

Keeping your appliances in top shape requires more than just basic knowledge; it demands the right tools. Personally, I rely heavily on a high-quality digital multimeter, such as the Fluke 117, because it provides accurate voltage and resistance measurements essential for diagnosing issues like faulty thermostats or wiring faults. Its true RMS function allows me to measure AC voltage reliably across different circuits, which is critical when testing refrigerator compressor wiring or oven heating elements.

Beyond multimeters, I use an infrared thermal camera, like the FLIR One, to detect uneven heat distribution and hidden electrical faults. For instance, spotting hotspots in refrigerator compressor connections saved me from costly replacement parts that weren’t actually defective. These tools empower me to conduct diagnostics confidently, minimize unnecessary repairs, and ultimately extend the lifespan of my appliances.

Utilizing Diagnostic Software and Manuals Effectively

Manuals are invaluable, but modern appliances often come with diagnostic software or built-in diagnostic modes accessible via control panels. I recommend familiarizing yourself with the manufacturer’s diagnostic procedures; for example, LG and Samsung models often have detailed diagnostic modes that can be initiated with specific button sequences. These modes can reveal error codes, like compressor lockouts or sensor failures, directly guiding repairs.

Additionally, diagnostic apps, such as the appliance manufacturer’s official apps or third-party diagnostic tools, can interface with appliances via Wi-Fi or Bluetooth, providing real-time data and troubleshooting steps. Using these tools saves time and reduces guesswork, particularly when dealing with complex systems like inverter compressors or electronic control boards.

Maintaining and Calibrating Your Equipment for Accurate Results

To ensure ongoing accuracy, regular calibration of your multimeter and thermal camera is essential. I send my multimeter to certified calibration centers annually. For thermal cameras, simple calibration procedures using known temperature references can be performed periodically. Accurate readings prevent misdiagnoses and costly unnecessary parts replacement, which is especially important when warranties are involved.

Predicting the Future of Appliance Maintenance

Looking ahead, I believe the integration of IoT sensors and AI-driven diagnostics will revolutionize appliance maintenance. Future tools will likely provide real-time health monitoring, predictive failure alerts, and automated diagnostics, reducing downtime and repair costs. Staying current with these technological advancements will prove invaluable for homeowners committed to long-term appliance care.

How can I maintain my appliances over time?

Regular cleaning, timely diagnostics, and proper calibration of your tools are vital. Schedule periodic inspections following expert guidelines like those found in this comprehensive guide. Always record diagnostic results and repair histories to track patterns and anticipate future issues.

If you haven’t already, try calibrating your multimeter today using a known resistor or voltage source. This small step can significantly improve diagnostic accuracy and save you money in the long run. For detailed calibration methods, visit our privacy policy for resources on equipment maintenance.

3 Unspoken Truths That Changed My Approach to Oven Repairs

- Trust the Process, Not Just the Parts: Rushing to replace components without proper diagnostics often led me astray. Precision in testing reveals the real culprit, saving money and future headaches.

- Warranties Are Worth Mastering: Many overlook warranty terms, unknowingly risking coverage. Knowing what’s covered turned simple repairs into guaranteed solutions.

- Tools Make or Break the Job: Investing in quality diagnostic equipment transformed my troubleshooting from guesswork to certainty, ensuring long-term appliance health.

- Document Every Step: Keeping detailed records during diagnostics streamlined repairs and strengthened warranty claims, reinforcing the importance of organized troubleshooting.

My Go-To Resources for Smarter Repairs

- Refrigerator troubles guide: Offers deep insights into diagnostics that I rely on for refrigerators but many principles apply across appliances.

- Oven repair secrets: This resource unlocked my understanding of precise diagnostics, crucial for effective repairs.

- Troubleshooting tips: Practical advice on avoiding unnecessary replacements and maximizing warranty benefits—a must-have for homeowners.

- Warranty insights: Helps to navigate warranty policies, ensuring repairs are covered when it counts most.

Step Forward with Confidence and Curiosity

Armed with real diagnostics, expert tools, and a clear understanding of warranties, you can approach oven repair with confidence. Remember, each troubleshooting journey enhances your skills and empowers you to make smarter decisions—turning appliance problems into learning opportunities. Keep honing your diagnostic technique, stay curious about new tools, and never hesitate to seek help when needed. Your appliances—and your wallet—will thank you. Have you ever faced a tricky oven repair and discovered something unexpected? Share your story below to inspire others on their repair adventures!

,

More Details